PCB Assembly

Full turn-key PCB assembly services specializing in prototype and low/mid-volume.

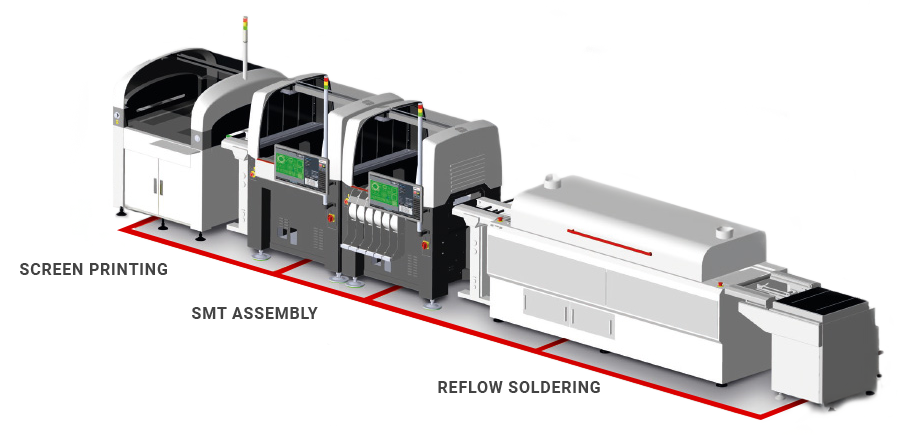

Our in-house SMT assembly line gives us full control over providing flexibility for prototypes, one-offs, and production runs. Whether you are looking to validate a new design, or ramp production, we can handle your production needs. With equipment optimized for high-mix, high component-count builds and robotic pick and place with optical placement, we handle all jobs with precision and reliability.

Sourcing & Supply Chain

Our proactive sourcing and supply chain expertise go far beyond just purchasing parts — we work to ensure your project stays on schedule and on budget:

-

Strategic Supplier Management: We negotiate not just on price, but also on custom delivery schedules, payment terms, and inventory strategies to reduce lead times and control costs.

-

Component Risk Mitigation: We identify long lead-time, end-of-life, or obsolete components early, providing timely alternatives to keep your build on track.

-

Continuous Collaboration: We work closely with your engineers to streamline BOMs throughout the process.

-

Cost Optimization: Leveraging volume purchasing when possible, we seek cost savings that don’t compromise performance or reliability.

From prototype sourcing to ongoing production supply, we manage the details so you can focus on your product.

Design for Manufacturability (DFM) Review & Collaborative Support

More than Assembly — We Help You Idea Succeed in Production

Getting a design production-ready takes more than just a schematic. REVO cuts straight to what matters — working alongside you to optimize and streamline your design for production.

Collaborative DFM reviews to identify assembly issues with recommendations for layout improvements, testability, and ease of manufacturing

Guidance on component selection, footprints, and sourceability

Seamless handoff between design, prototyping, and full production

Why REVO?

With vertically integrated design and assembly under one roof, we close the gap between engineering and manufacturing—delivering higher quality, faster cycles, and responsive support every step of the way.